For the final in Designing for Digital Fabrication, I’ll be refining my PComp “Mic Cuff” build into a more professional form. I needed to do my first 3D print ever. First off, measurements:

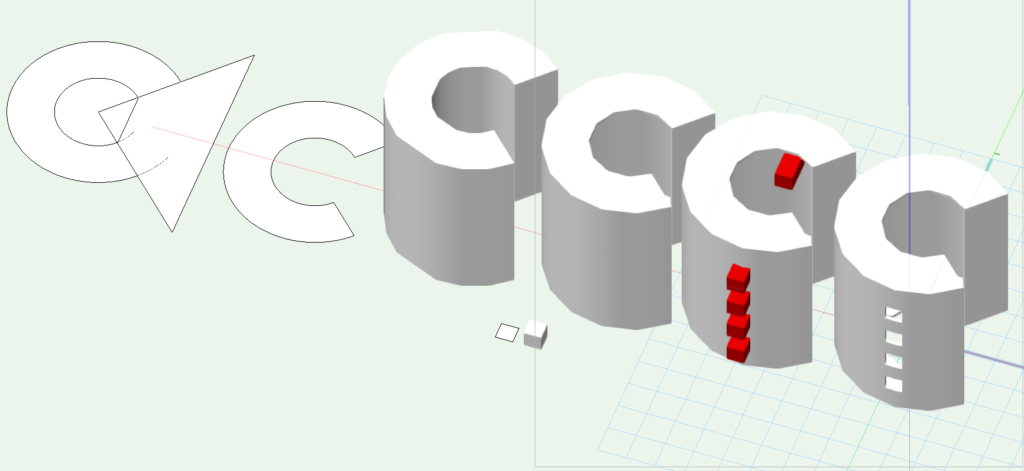

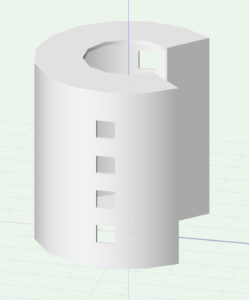

Then, after a mockup in Vectworks:

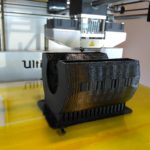

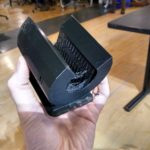

It took a little bit of finessing to get the print time down, but I wound up with a functional print at the end! Beginners luck? I’ll take it.

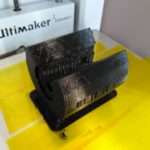

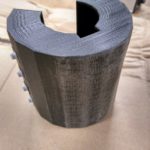

Pulling off the supports, and then trying to press in the buttons… turns out I didn’t give myself enough space for a proper “press fit”:

So it was dremel time!

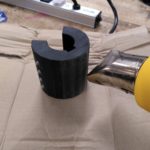

There were some marks where the supports were sanded away. It felt smooth enough, but I wanted to try getting it at smooth as possible, so I used the heat gun:

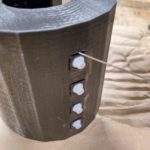

This didn’t smooth out the chalky parts, and started to warp the plastic itself (worst of both worlds) so I stopped. I started thinking about ways to secure the buttons into the freshly dremeled slots, and got an idea:

The PLA solvent could be used to bind the buttons into the slots, but also perhaps add a bit of gloss (or just get rid of the white residue).

After letting the solvent set, some of the buttons did pop out. So I will probably need to do some traditional epoxy glue instead. But for now, I’m pretty happy with how the first pass went. I’ll wire up the buttons and think about cable management for the next week.